Dual Plate Check Valves Manufacturer and Exporter in Ahmedabad

We are a trusted manufacturer and exporter in Ahmedabad offering durable, high-performance valves for industrial applications.

What is Dual Plate Check Valves?

Dual Plate Check Valves, also known as double-door or butterfly check valves, are compact mechanical devices designed to automatically allow fluid flow in one direction while preventing potentially damaging reverse flow. Their innovative design features two spring-loaded semi-circular plates hinged on a central pin, all housed within a remarkably slim, lightweight body. This configuration makes them significantly more compact than traditional swing check valves while offering superior performance characteristics.

XSIS Automatic Valves in Ahmedabad are designed with precision engineering and durable materials to provide high performance, reliability, and energy efficiency for various industrial applications.

How Does Dual Plate Check Valves Work?

The operational principle begins when forward flow conditions push fluid pressure against the two hinged plates, forcing them to rotate open around the central pin against spring tension.

This creates an unobstructed flow path for the medium. When upstream flow diminishes or reverse flow commences, the torsion springs instantly actuate, snapping the plates closed. The backflow pressure simultaneously assists in sealing the plates tightly against the valve seat, ensuring leak-proof shut-off and preventing backflow.

XSIS Automatic Valves in Ahmedabad are designed with precision engineering and durable materials to provide high performance, reliability, and energy efficiency for various industrial applications.

The operational principle begins when forward flow conditions push fluid pressure against the two hinged plates, forcing them to rotate open around the central pin against spring tension.

This creates an unobstructed flow path for the medium. When upstream flow diminishes or reverse flow commences, the torsion springs instantly actuate, snapping the plates closed. The backflow pressure simultaneously assists in sealing the plates tightly against the valve seat, ensuring leak-proof shut-off and preventing backflow.

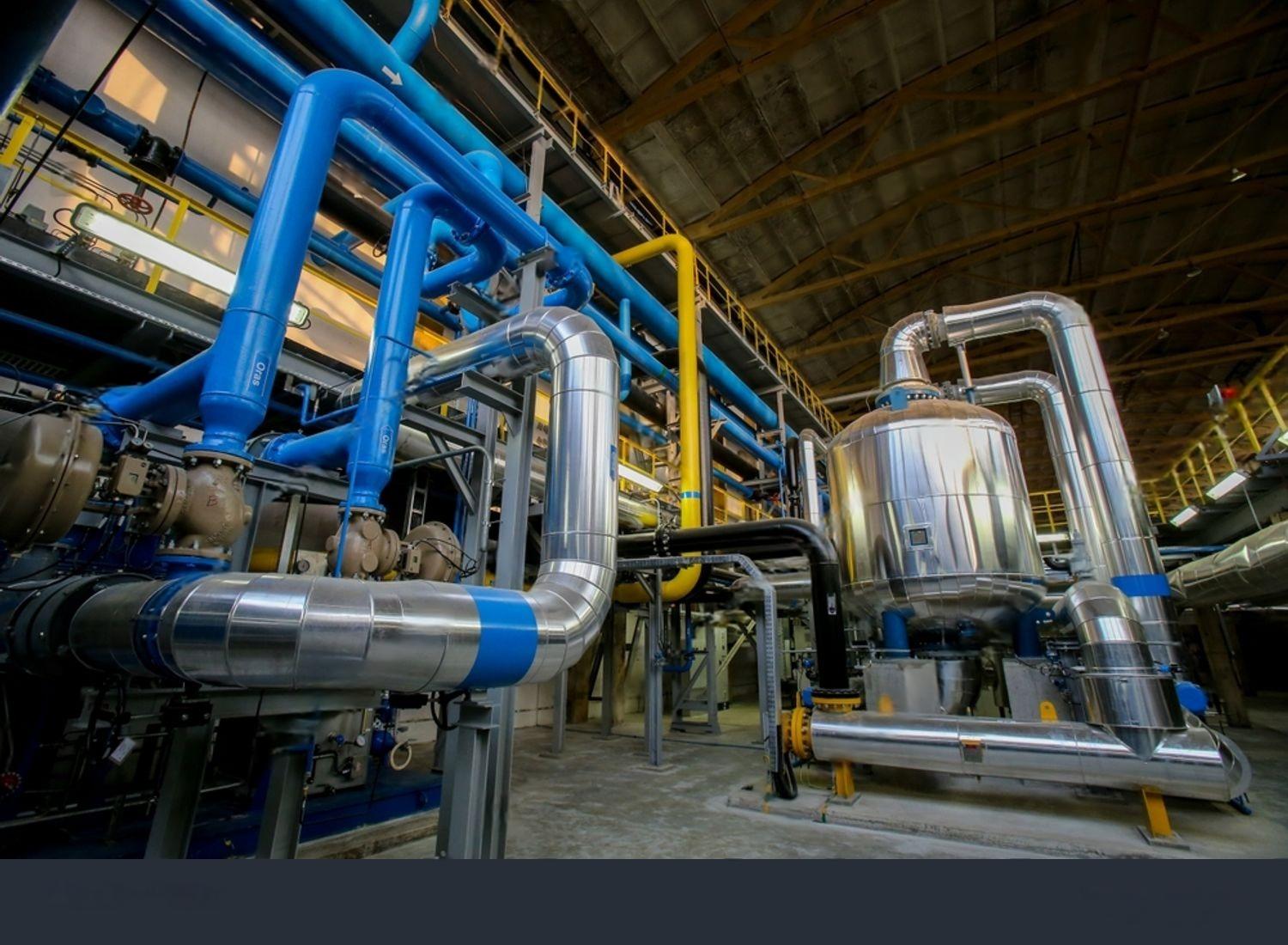

These valves serve critical functions across diverse industrial sectors including oil and gas pipelines, water treatment facilities, power generation plants, and chemical processing systems.

Their reliability makes them suitable for fire protection systems, HVAC applications, and various industrial processing plants where unidirectional flow control is essential for operational safety and efficiency.

Why Choose XSIS Valves?

As one of the top valve manufacturers and exporters in Ahmadabad, we combine innovation, quality, and precision to deliver valves that perform consistently across industries.

Our Competitive Advantages:

Proven Expertise: 17+ years of trusted valve manufacturing experience.

Global Reach: Recognized valve exporter in Ahmadabad with clients across multiple countries.

Uncompromised Quality: Adherence to ISO 9001:2015 and international standards.

Durability & Reliability: Valves designed for long-lasting operation in harsh environments.

Customization: Tailor-made valve solutions for diverse industrial needs.

Sustainability Focus: Environmentally responsible manufacturing processes.

Served By

We provide a comprehensive selection of valves tailored for various industries in Ahmadabad, including Plumbing, HVAC, Fire-Fighting, Power, Oil & Gas, Steel & Mining, Boilers, Pharmaceuticals, Chemicals & Fertilizers, LNG, Cryogenics, and Marine applications. Our in-house design facility utilizes advanced computer modeling software to engineer specialized valves for critical applications.

Oil & Gas

LNG & Cryogenic

Marine & Water

Chemicals & Fertilizer

Steel & Mining

Power

Advantages Of Dual Plate Check Valves

- Due to its compact design and lightweight, it’s easier to install it and occupies very less space in the pipeline.

- It’s flow path is designed in a way, when fluid passes through it, pressure reduces due to which

- less energy is used in pumping.

- As compared to traditional valves it is very lightweight which can be easily handled and requires low maintenance cost.

- Risk of water hammering reduces due to spring which helps in quick closing.

- It can be installed easily in horizontal as well as vertical pipeline.

- Due to quick and controlled closing action, vibration and noise also reduces.

- Being lightweight and compact in design material used for its construction is very less and makes it cost efficient as compared to other check valves of bigger size.

- It’s spring and very few moving parts require very low maintenance.

Maintenance Tips for Dual Plate Check Valves

-

- Regular Inspection- One should regularly check the valve body and flange connections at fixed intervals. Due to which any visible damage or leakage can be identified and repaired in time.

- Monitor for ‘Water Hammer’ / Noise- If there is a water hammer sound or too much noise during valve operation, it generally means that the disc mechanism is not sealing properly or there must be a problem with the spring tension.

- Check Bolt Tightness– If the bolts are loose leakage can occur so keep checking the tightness of the flange and body bolts with a torque wrench.

- Examine Sealing Surfaces- When the valve is shut down for maintenance, examine the sealing surfaces of the disc and seat thoroughly. Erosion or pitting can cause poor sealing

- Inspect Spring and Hinge Pin- Springs are very important in DPCVs. Check that the springs aren’t damaged or fatigued. It is also necessary to check the smooth movement of the hinge pin

- Debris/Foreign Material Removal- Debris or foreign material present in the system can obstruct disc movement. To avoid this, use strainers and keep the valve internals clean.

- Correct Installation and Alignment- Ensure that the valve is always installed according to manufacturer guidelines, in the proper direction, and with correct pipe alignment. Misalignment increases stress on internal parts.