Strainer Valves Manufacturer and Exporter in Ahmedabad

XSIS Valves is a trusted Strainer Valves Manufacturer and Exporter in Ahmedabad. We deliver high-quality valves designed for efficient filtration and flow protection.

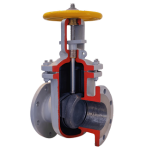

What is a Valve Strainer?

A strainer is a mechanical device used to remove unwanted particles such as rust, dirt, or debris from the flow of liquid or gas within a pipeline. It acts as a filter that ensures smooth operation and prevents damage to machinery and equipment.

XSIS Strainers in Ahmedabad are designed with durable materials and advanced technology to ensure reliability and long-term efficiency. They are an essential component in every industrial pipeline system to maintain safety and consistent flow.

A strainer works on a simple filtration mechanism. When the fluid or gas flows through the system, it passes through a mesh or perforated screen inside the strainer. The screen traps larger particles and allows only clean fluid to move forward.

This prevents clogging and damage to pumps, valves, and other equipment. XSIS Strainers are built with precision to minimize pressure loss, reduce maintenance time, and enhance overall system performance.

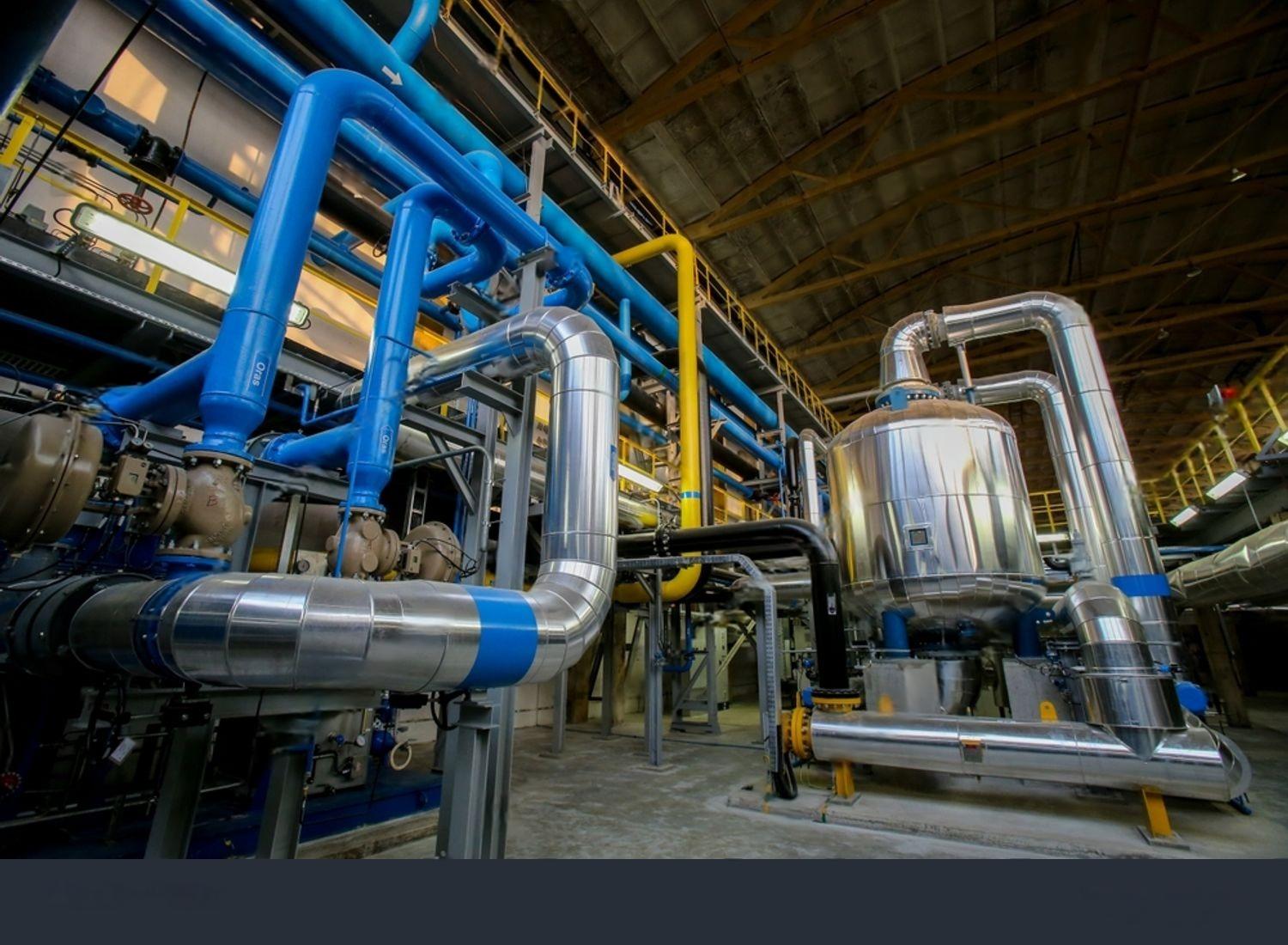

Strainers are used across various industries such as water treatment, oil & gas, chemical plants, marine applications, and HVAC systems. They ensure that the flow remains clean and equipment is protected from contaminants.

XSIS Strainers are suitable for both industrial and commercial setups and can be integrated with pumps, compressors, and pipelines to ensure reliability and smooth functioning.

Why Choose XSIS Valves?

As one of the top valve manufacturers and exporters in Ahmadabad, we combine innovation, quality, and precision to deliver valves that perform consistently across industries.

Our Competitive Advantages:

Proven Expertise: 17+ years of trusted valve manufacturing experience.

Global Reach: Recognized valve exporter in Ahmadabad with clients across multiple countries.

Uncompromised Quality: Adherence to ISO 9001:2015 and international standards.

Durability & Reliability: Valves designed for long-lasting operation in harsh environments.

Customization: Tailor-made valve solutions for diverse industrial needs.

Sustainability Focus: Environmentally responsible manufacturing processes.

Served By

We provide a comprehensive selection of valves tailored for various industries in Ahmadabad, including Plumbing, HVAC, Fire-Fighting, Power, Oil & Gas, Steel & Mining, Boilers, Pharmaceuticals, Chemicals & Fertilizers, LNG, Cryogenics, and Marine applications. Our in-house design facility utilizes advanced computer modeling software to engineer specialized valves for critical applications.

Oil & Gas

LNG & Cryogenic

Marine & Water

Chemicals & Fertilizer

Steel & Mining

Power

Advantages of Using Valve Strainer

- Protects pipelines and equipment from debris and blockages

- Extends the lifespan of machinery

- Reduces downtime and maintenance costs

- Improves energy efficiency and performance

- Minimizes pressure loss in the system

- Easy to install, clean, and maintain

- Enhances operational reliability

- Ensures consistent flow quality and uninterrupted performance across industrial processes

Key factors to consider when choosing a Strainer

Selecting the right strainer depends on several key factors that influence its performance and durability:

- Fluid Type and Particle Size – Choose the appropriate mesh size depending on the type of contaminants in the fluid.

- Pressure and Temperature Rating – Make sure the strainer can handle the working conditions of your system.

- Material Compatibility – Stainless steel, bronze, or carbon steel should be selected based on the chemical nature of the fluid.

- Installation Space and Orientation – Consider the available space and layout before choosing the type of strainer.

- Ease of Cleaning and Maintenance – Basket or duplex strainers are ideal for systems that require frequent cleaning.

- Spare Part Availability and Supplier Reliability – Always prefer reputed suppliers like XSIS that offer quality assurance and easy availability of replacement parts.

- Certification and Quality Standards – Ensure that the strainer meets industrial standards for safety and performance.

Maintenance tips for long-lasting performance

Proper maintenance plays a vital role in ensuring the long life and consistent efficiency of a strainer:

- Clean and inspect the strainer regularly to prevent clogging.

- Monitor inlet and outlet pressure; a high-pressure drop indicates cleaning is needed.

- Replace damaged or worn-out parts promptly to avoid leakage or contamination.

- Keep all seals and movable parts properly lubricated.

- Follow a scheduled maintenance plan to reduce downtime and ensure reliability.

- Use monitoring tools for automatic alerts in case of blockage or reduced performance.

- Maintain proper records of all cleaning and maintenance activities for future reference.