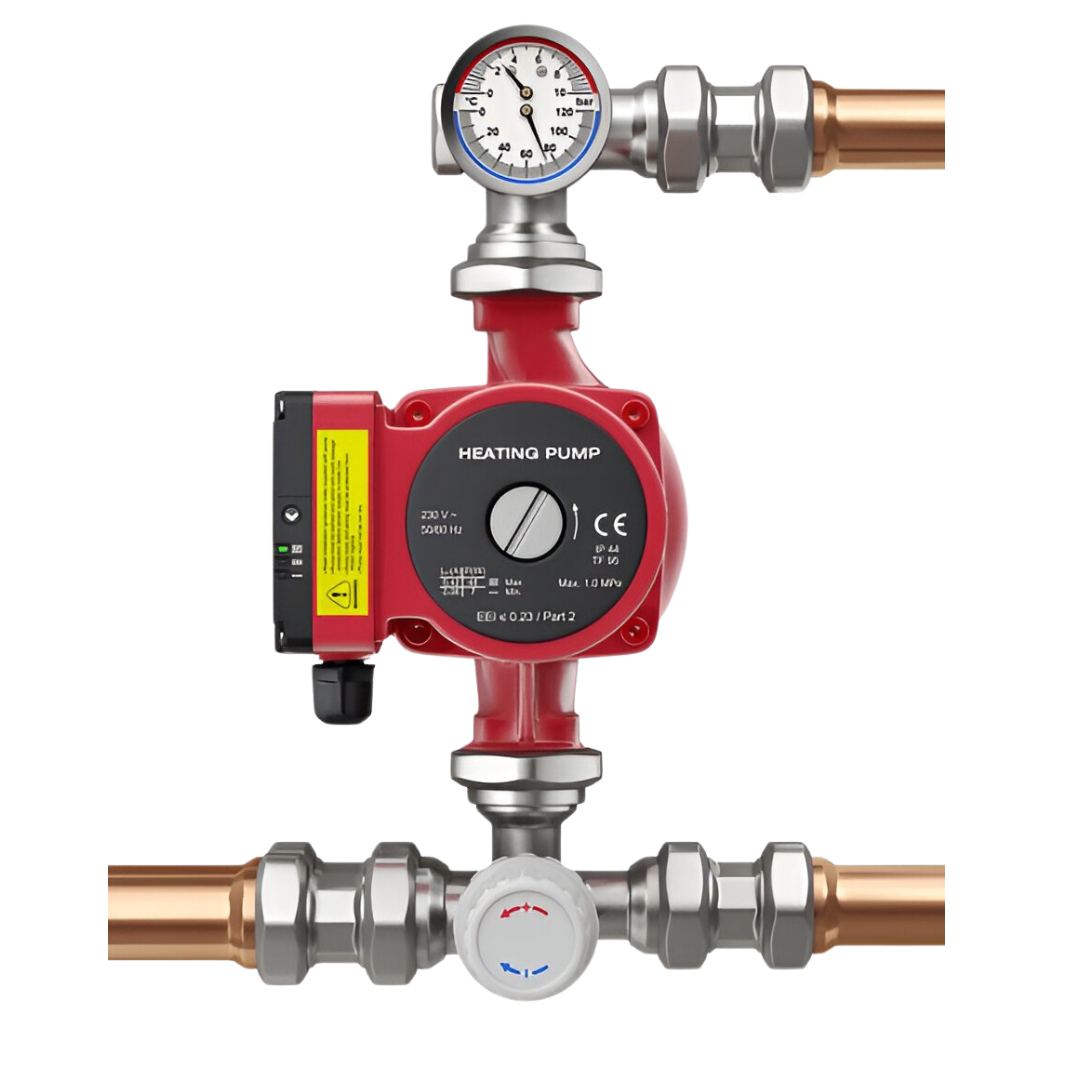

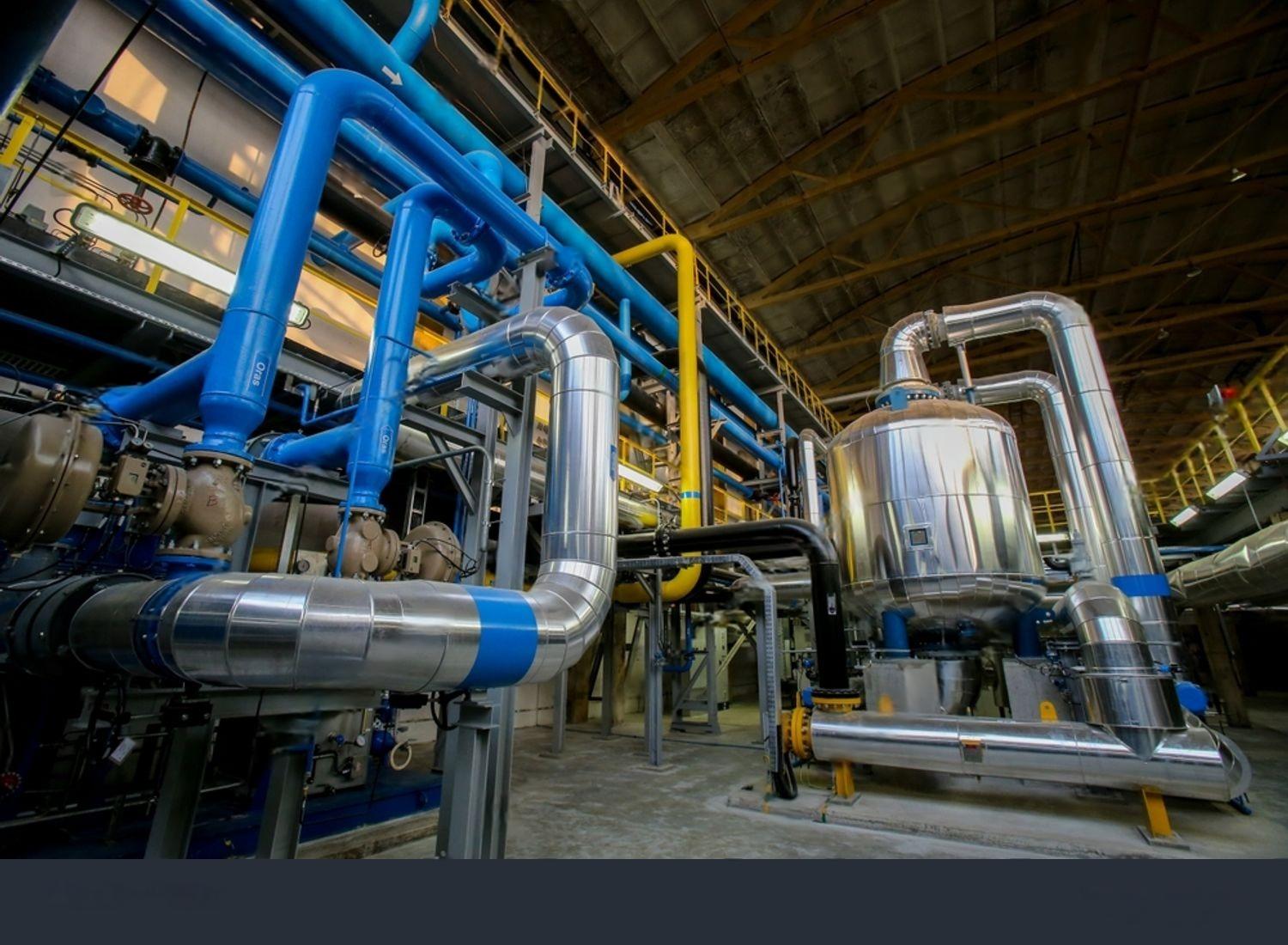

Check Valves are used in HVAC, chemical industries, supply chain, oil & gas pipelines, marine and wastewater treatment. Its presence makes pumps and compressors flow more reliable and secure. These valves reduce the downtime and improve process efficiency in industrial and commercial pipelines. XSIS’s Check Valve in Ahmadabad is trusted solution in multiple industries.

Check Valve in Ahmedabad

Check Valve Manufacturer and Exporter in Ahmedabad

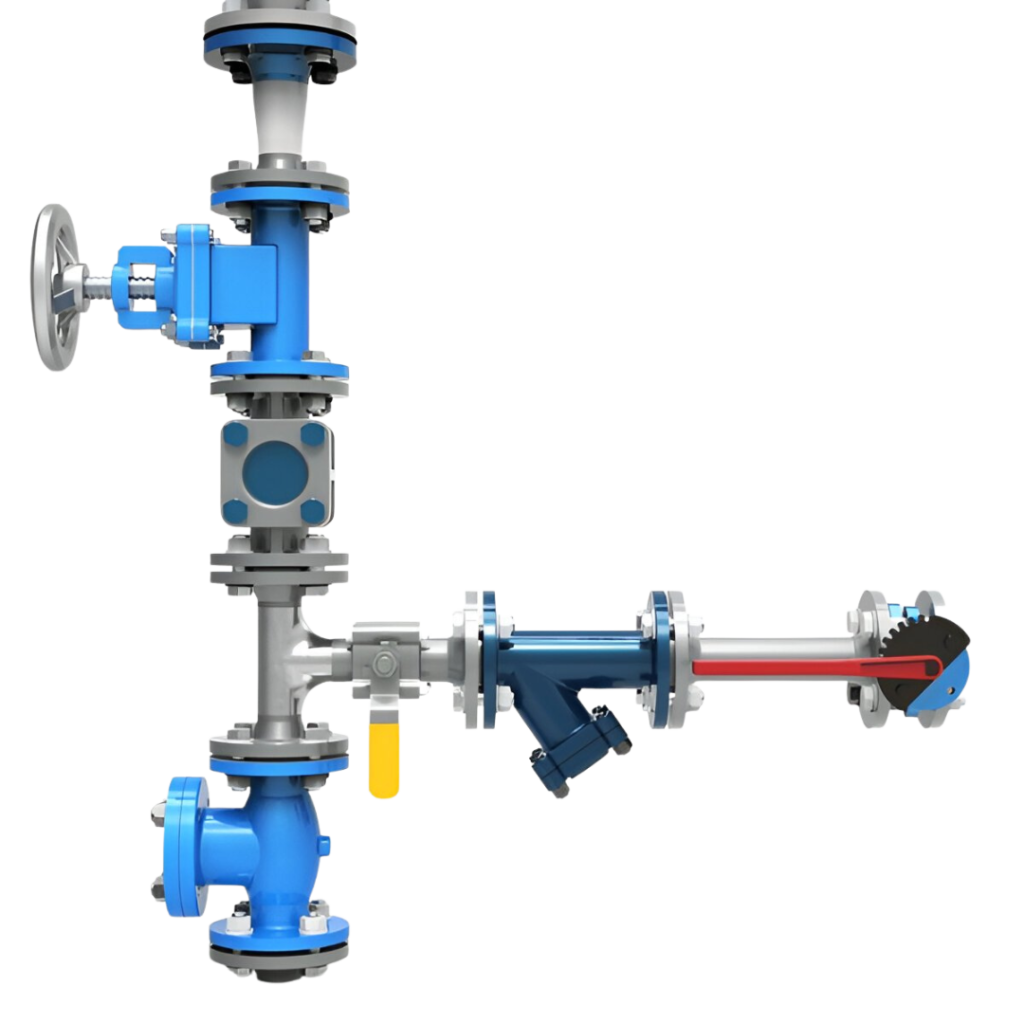

XSIS Valves is a trusted Check Valve Manufacturer and Exporter in Ahmedabad. We offer durable and precision-engineered Check Valves for efficient flow control systems.

Premier Check Valve Manufacturer in Ahmedabad

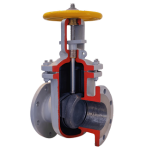

What is Check valve?

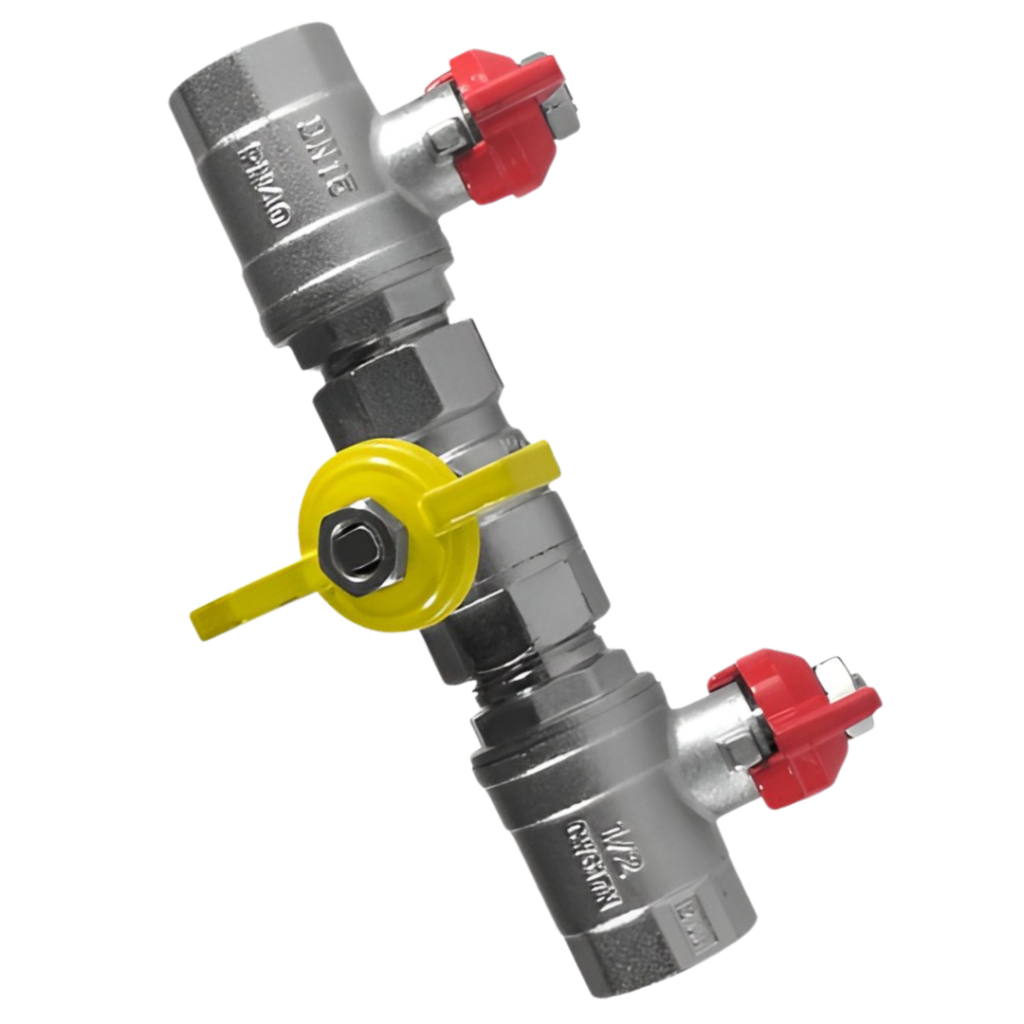

Check Valve is a one-way valve that helps fluid to flow in one direction and prevents from backflow. This valve saves pipeline and machinery from damage and maintains the efficiency and safety of system. XSIS’s Check Valve in Ahmadabad is made from high quality materials that provide reliable solution to commercial and industrial application. These valves come with low maintenance and provide long-term durability. Moreover reduces the operational cost.

Trusted Check Valve Manufacturer in Ahmedabad

Types of Check Valve

1. Ball Check Valve

It has compact design and easy to install.

2. Swing Check Valve

It’s ideal for large pipelines. Provides smooth flow.

3. Dual Plate Check Valve

- It offers low pressure drop and is highly energy efficient.

4. Lift Check Valve

- It maintains the precise flow in high-pressure application.

Check Valve Manufacturer and Exporter in Ahmedabad

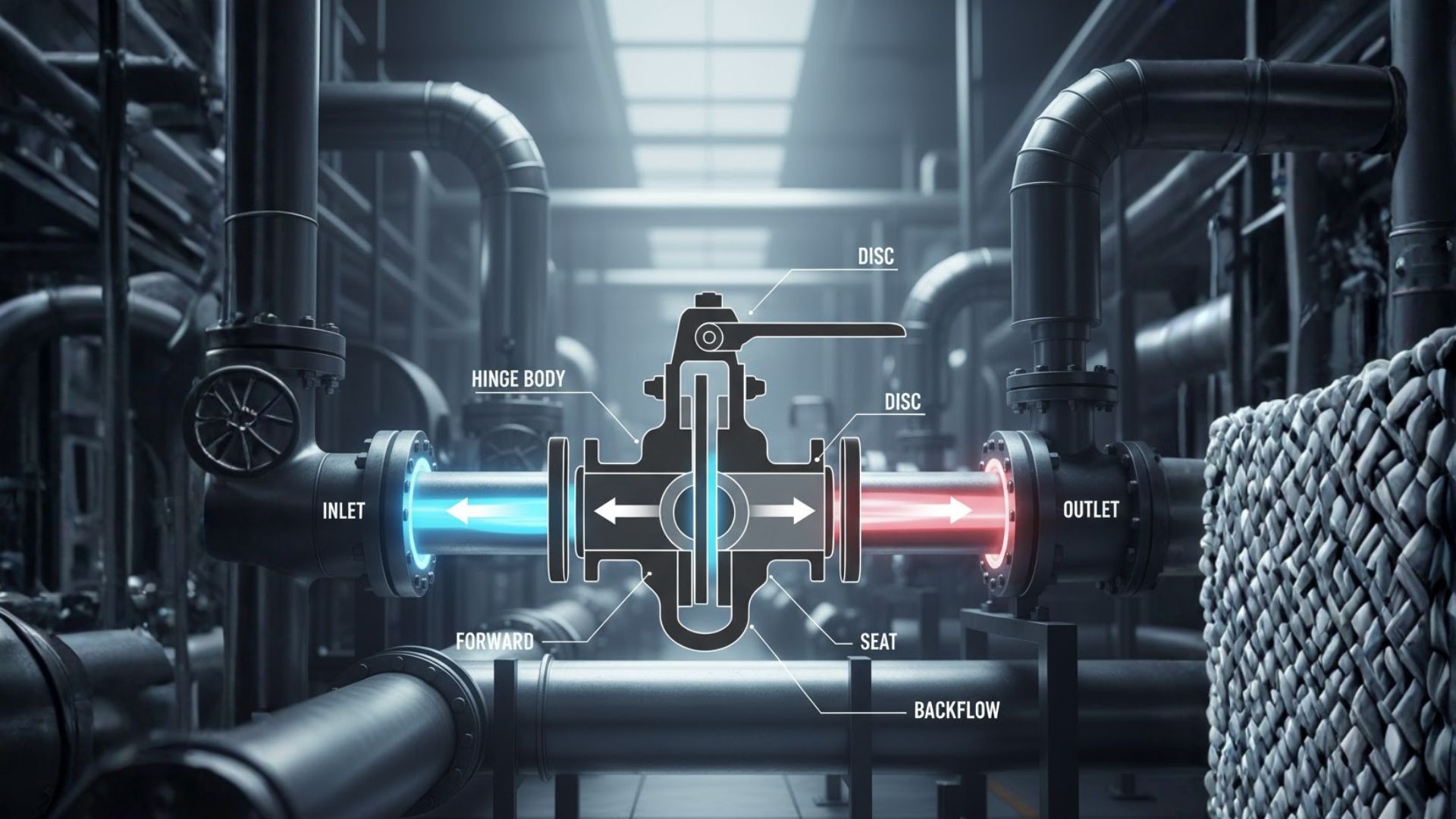

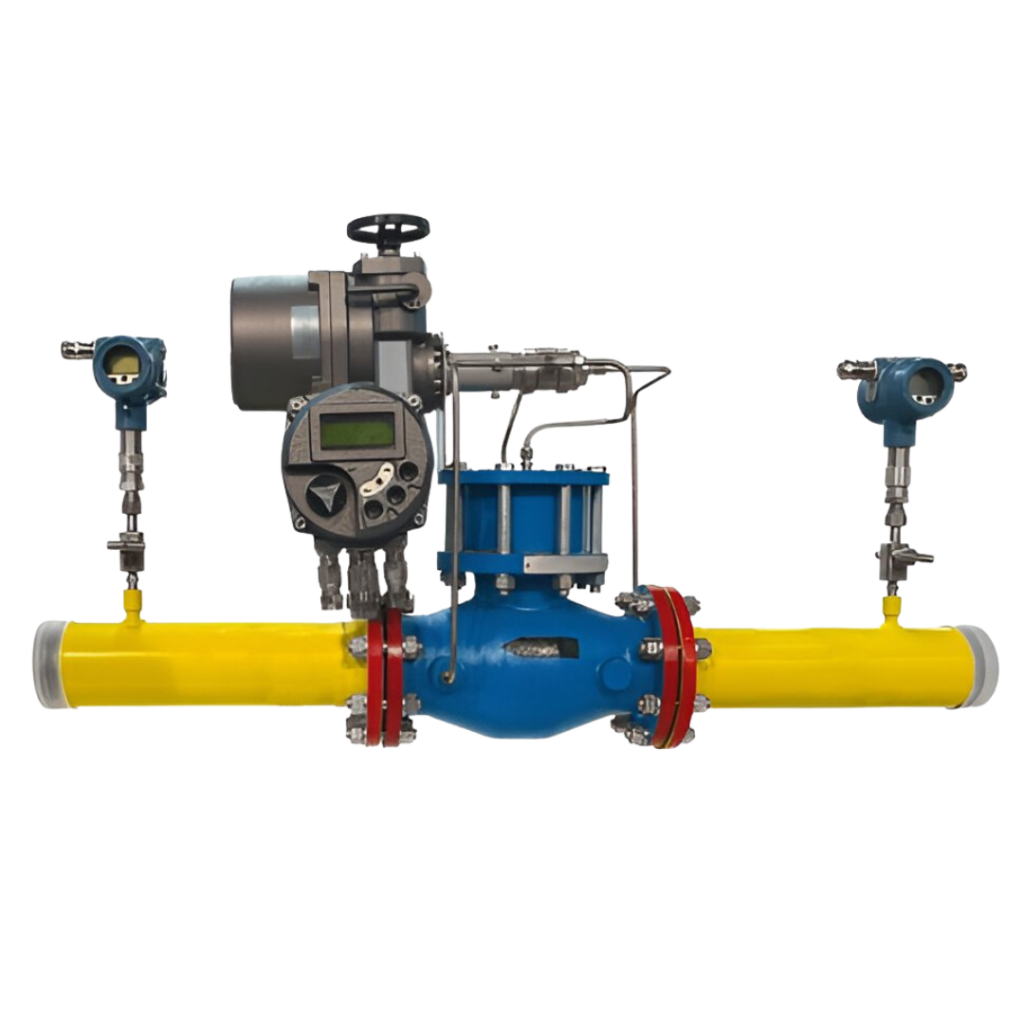

How does a Check Valve work?

Mechanism of check valve is simple. When fluid flows forward the valves open up. If the flow gets reverse the valve closes automatically and prevents backflow. Its internal components like disc, swing or ball reacts on the pressure of flow. This ensures the stability, safety and efficiency in the system. Check valves helps in reducing downtime and maintenance cost of industrial pipeline.

[ +]

Current Clients

[ +]

years of experience

[ +]

Credentials

Why Choose XSIS Valves?

As one of the top valve manufacturers and exporters in Ahmadabad, we combine innovation, quality, and precision to deliver valves that perform consistently across industries.

Our Competitive Advantages:

Proven Expertise: 17+ years of trusted valve manufacturing experience.

Global Reach: Recognized valve exporter in Ahmadabad with clients across multiple countries.

Uncompromised Quality: Adherence to ISO 9001:2015 and international standards.

Durability & Reliability: Valves designed for long-lasting operation in harsh environments.

Customization: Tailor-made valve solutions for diverse industrial needs.

Sustainability Focus: Environmentally responsible manufacturing processes.

Xsis Valves

Our Recent Blogs

Dual plate check valves are widely used in industries where smooth flow control, space-saving design, and low pressure drop are important. From oil & gas to water treatment and process industries, these valves help prevent backflow while ensuring efficient performance. Ahmedabad is home to several reliable manufacturers offering high-quality dual plate check valves for domestic […]

Every successful industrial operation depends on reliable flow control systems, and forged steel valves play a critical role in ensuring safety, durability, and performance. Choosing the right Forged Steel Valves Companies in Ahmedabad can significantly impact operational efficiency, compliance, and long-term cost savings. Below is a curated list of the Top Forged Steel Valves Manufacturer […]

Selection of Industrial Valves does not depends simply on brand reputation or price. In today’s competitive environment, selection of Valve manufacturers is a strategic decision that directly impacts on safety, plant efficiency, and compliance. This guide will help you in simplifying decision making about the benefits of Certified Valve Manufacturer in Ahmadabad. What makes a […]

Industrial Valves might seem very small but it actually decides the safety, efficiency, and uptime of whole plant. What can happen if one chooses wrong valve manufacturer? It will result in production loss, breakdowns, high maintenance cost, and frequent leakages. So if you are in midst of How to choose the Best Industries Valves Manufacturer, […]

“What is a Check Valve?” is answered by its function: Check Valve is a one-way valve that helps fluid to flow in one direction and prevents from backflow. This valve saves pipeline and machinery from damage and maintains the efficiency and safety of system. XSIS’s Check Valve in Ahmadabad is made from high quality materials […]

Top Check Valve Manufacture in Ahmadabad

Served By

We provide a comprehensive selection of valves tailored for various industries in Ahmadabad, including Plumbing, HVAC, Fire-Fighting, Power, Oil & Gas, Steel & Mining, Boilers, Pharmaceuticals, Chemicals & Fertilizers, LNG, Cryogenics, and Marine applications. Our in-house design facility utilizes advanced computer modeling software to engineer specialized valves for critical applications.

Oil & Gas

LNG & Cryogenic

Marine & Water

Chemicals & Fertilizer

Steel & Mining

Power

Advantages of using of Check Valve

- It gives protection from backflow.

- Equipment increases the life.

- It saves energy and cost.

- It is easy to install and low maintenance cost.

- It ensures long-term performance with its reliable and durable design.

- It is effective in industrial environment due to corrosion-resistant material.

Key factors to consider when choosing Check Valve

- Type of fluid and its temperature/ pressure rating.

- Material used in construction (cast iron, stainless steel, PVC)

- Size of Valve and capacity.

- Types of check valve (swing. Ball, lift, dual plate).

- Space for installation and operational requirements.

- One should also consider the supplier reliability and certification.

Maintenance tips for Check Valve

- Regular inspection and cleaning of seat, disc, and sealing.

- Use of lubrication where required for smooth movement.

- Replacement of worn-out parts timely.

- Regular check for leakage and monitoring of pressure.

- Follow the schedule of preventive maintenance.

- Avoid operating in extreme conditions to save valve from damage.

- The life span and performance of valve increases when handled properly.