Looking for a trusted Forged Steel Gate Valve manufacturer? Xsis Valves is a trusted manufacturer and exporter in Ahmedabad, Gujarat. Check now!

Forged Steel Gate Valve in Ahmadabad

Industrial Forged Steel Valve in Ahmedabad

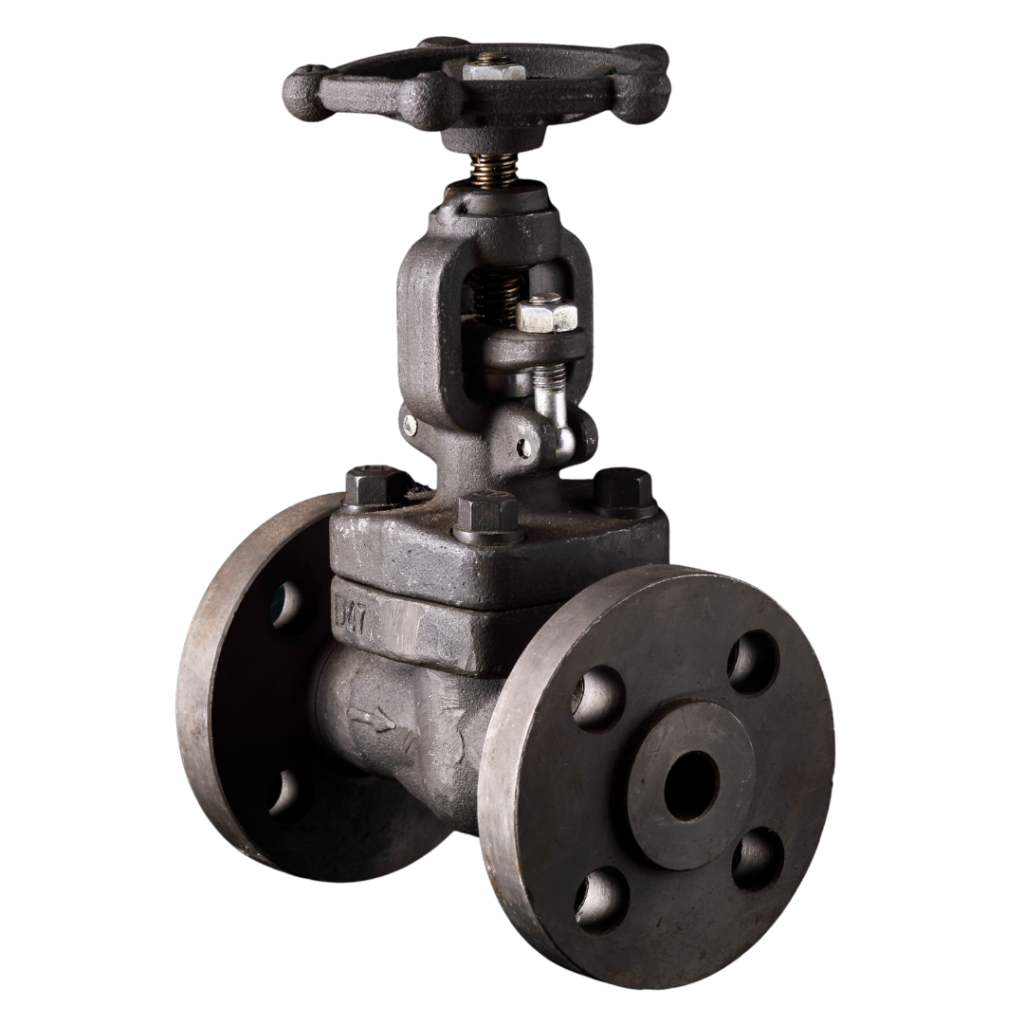

What Is Forged Steel Gate?

Forged steel valves are strong, high strength products that are forged. This is done in order to align metal grains to provide maximum structural integrity. These valves are required in numerous sectors in Ahmedabad which require different designs and accommodate the local water and gas quality, temperature and pressure. Their design particularly for gate, globe, and lift check types makes them ideal for critical, high-pressure, and high-temperature applications common in Ahmedabad’s chemical and petrochemical industries.

Trusted Forged Steel Valve Manufacturer in Ahmedabad

Types of Forged Steel Gate, Globe and Lift Check Valves

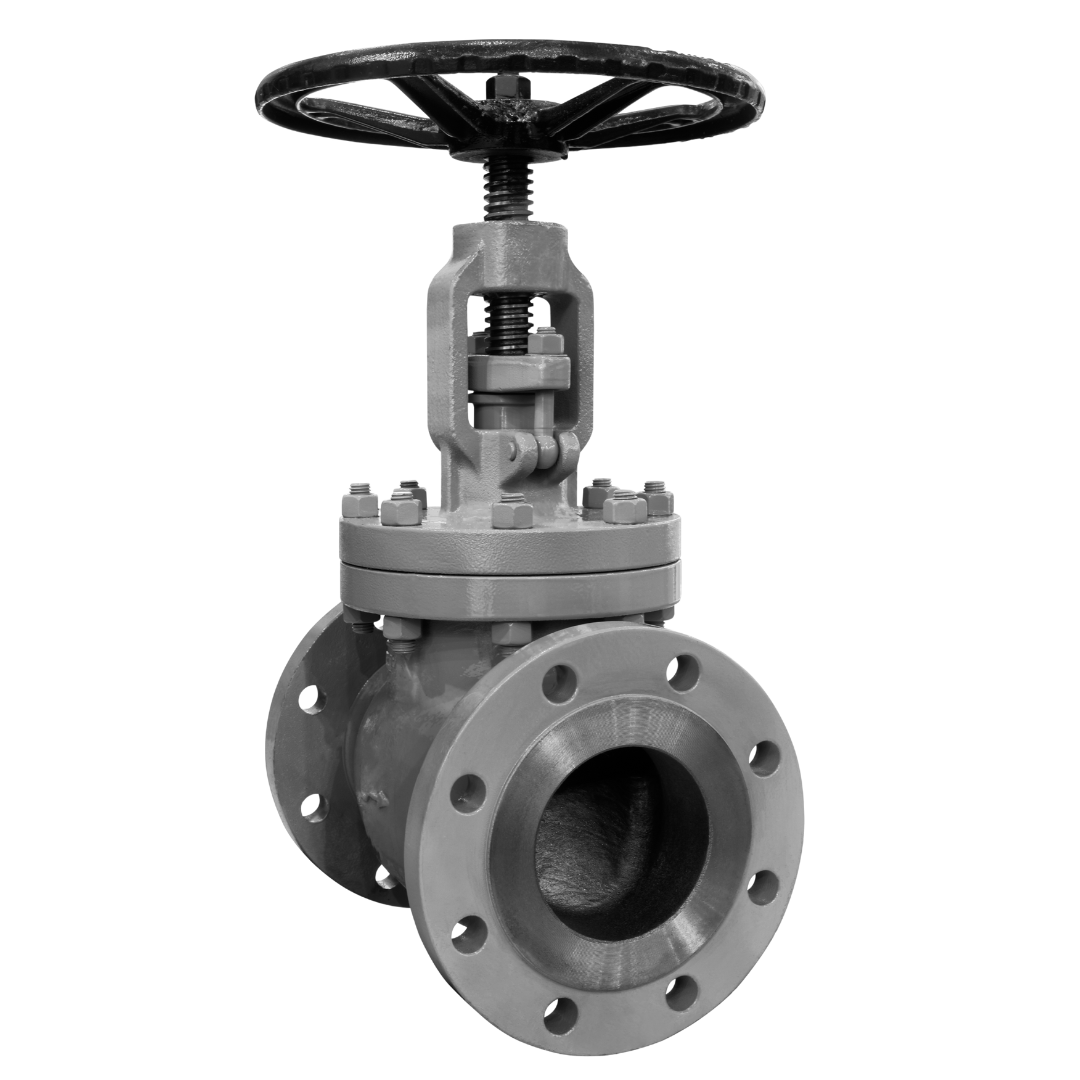

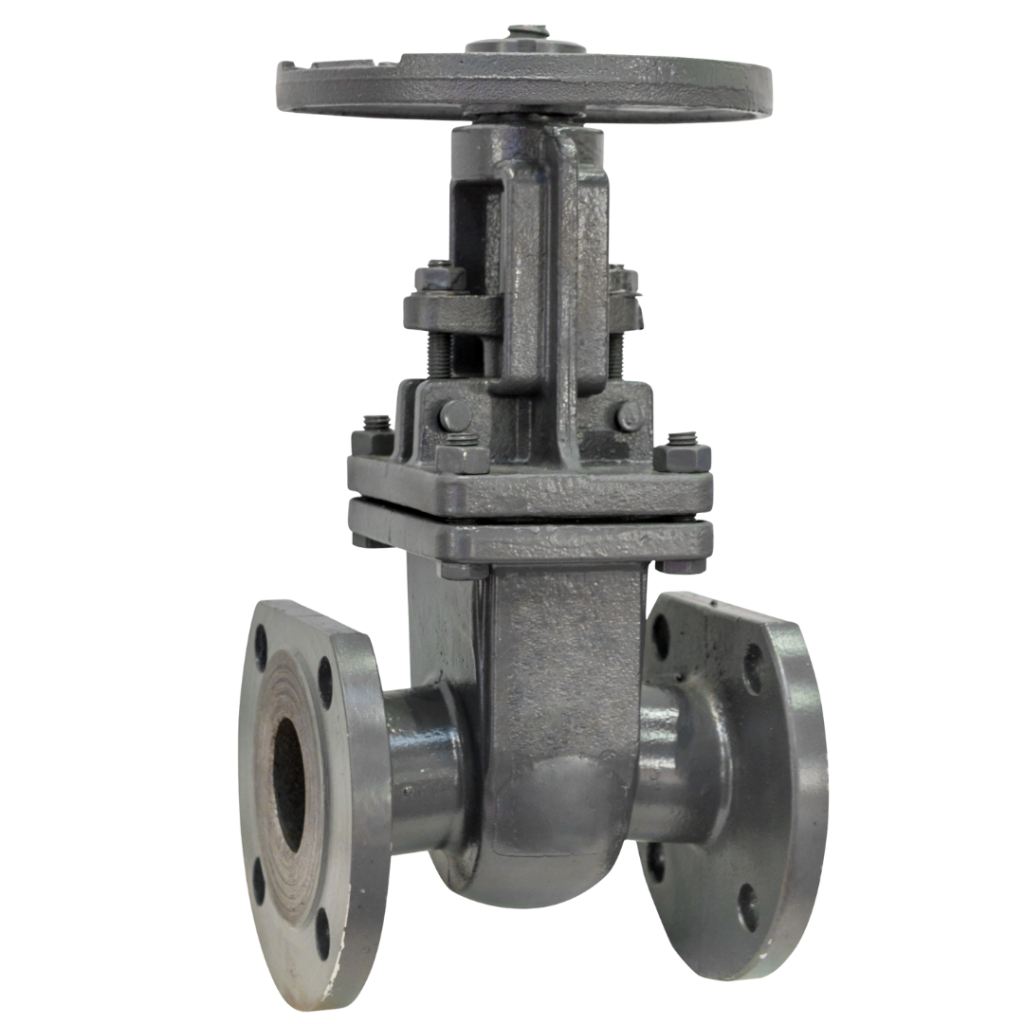

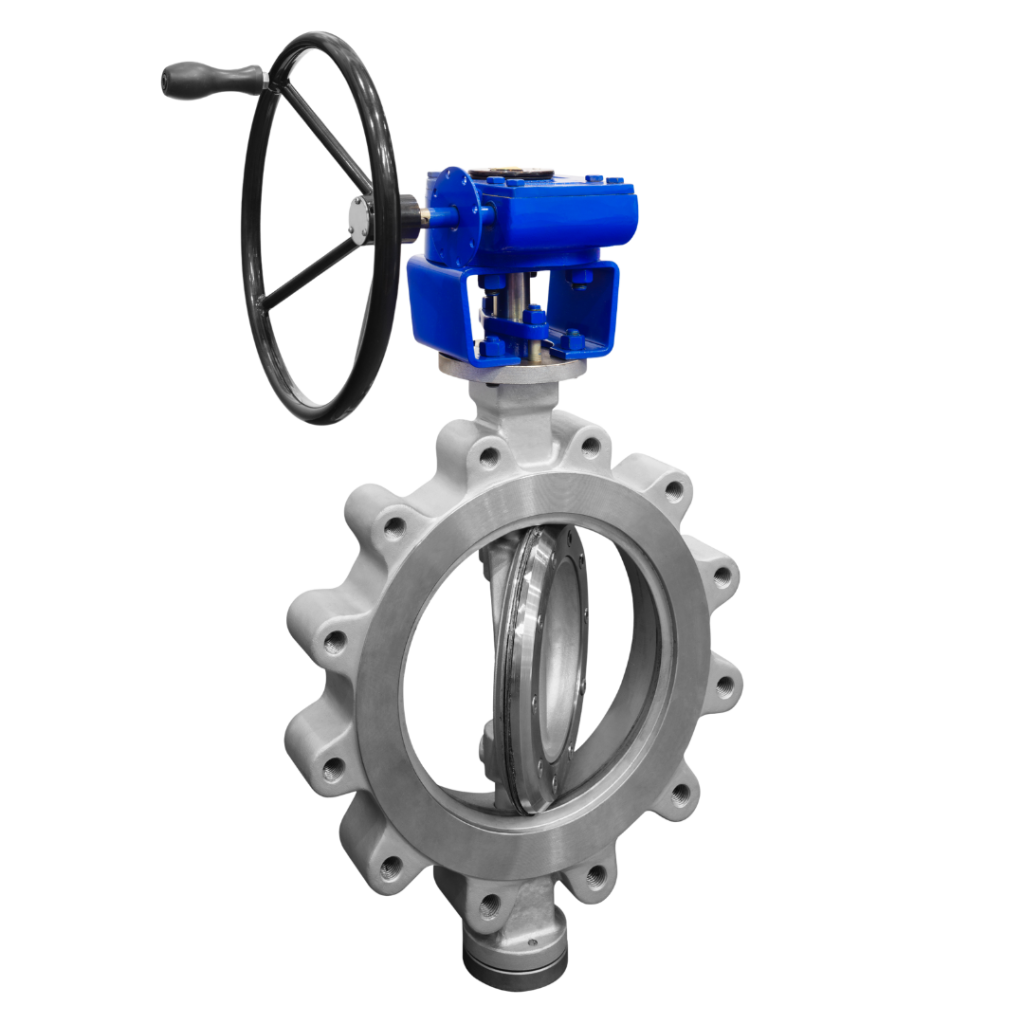

1. Gate Valves

These consist of a single flat plate which slides open or close. When fully open they have virtually zero flow resistance, and are designed in on-off mode for water treatment and desalination.

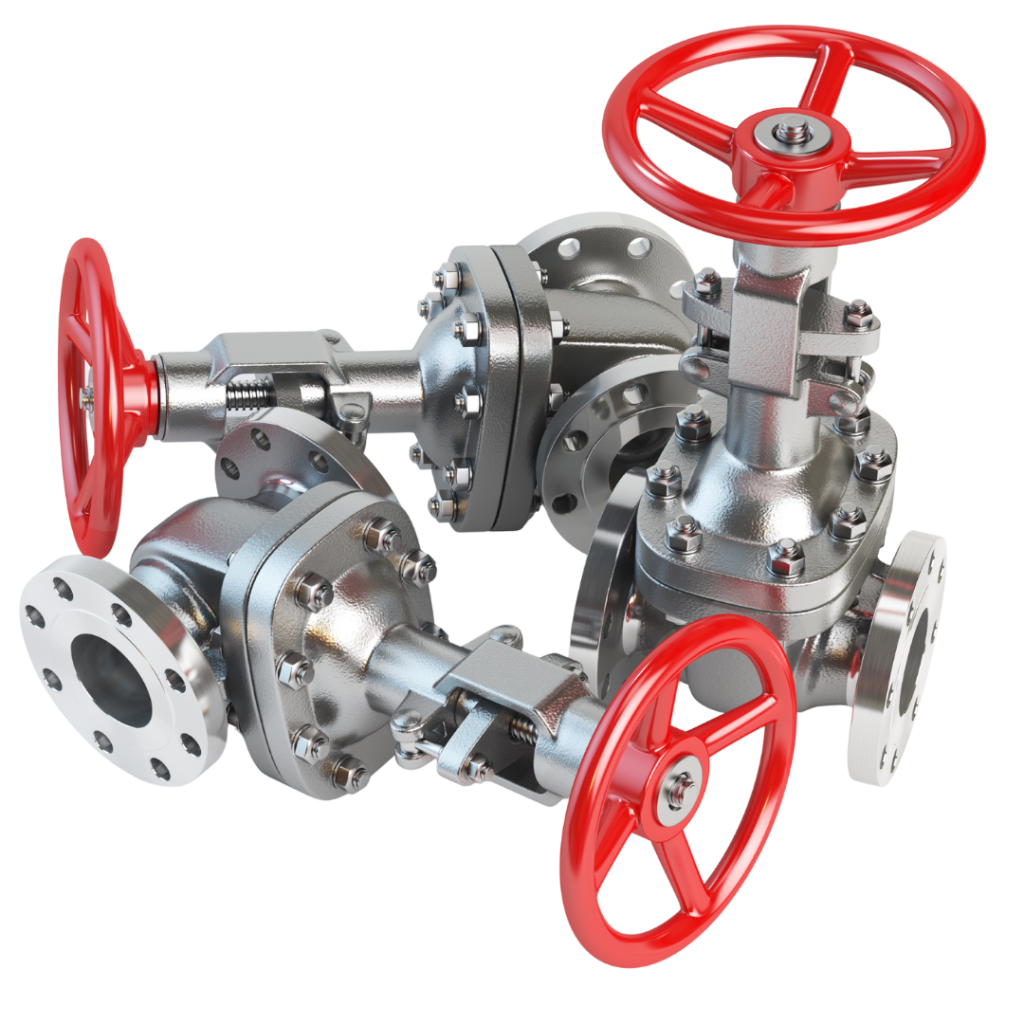

2. Globe Valves

- Globe valves are made up of disc and a spherical body moving. They are suited to throttling, fine control of flow rates in the chemical processing and oil refineries.

3. Lift Check Valves

Lift check valves do not allow any flow in the opposite direction and will prevent back-flow automatically. They are often used in water pumps and wastewater systems where they are highly useful because of their simple and reliable operation.

4. Relevant Valves Electric

Lift check valves do not allow any flow in the opposite direction and will prevent back-flow automatically. They are often used in water pumps and wastewater systems where they are highly useful because of their simple and reliable operation.

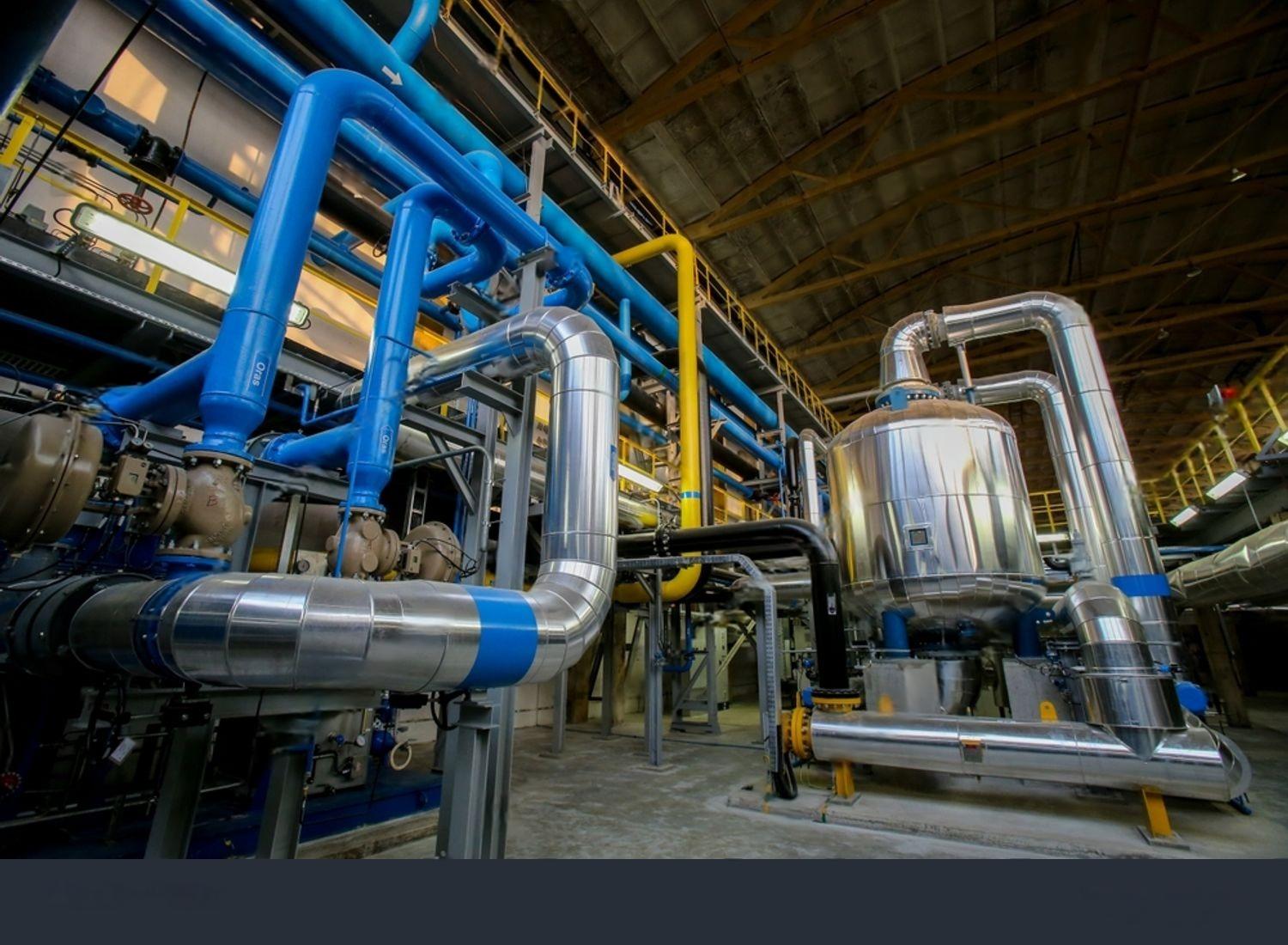

Industrial Forged Steel Valve Manufacturer and Exporter in Ahmedabad

How Does Forged Steel Gate Valve Works?

Stamped steel valves have been based on mechanical motion and sealing. A sliding gate of the valve closes over a seat. The disc of a globe valve moves within a chamber altering the cross-sectional area.

In lift check valve, the disc will rise as the pressure exceeds a certain value and will fall as the pressure decreases.

Each valve has a uniform microstructure which is attained during the forging process that maintains the seat, disc and body tough at high pressures and temperatures.

[ +]

Current Clients

[ +]

years of experience

[ +]

Credentials

Leading Forged Steel Valve Manufacturer and Exporter in Ahmedabad

Application of Forged Steel Gate

- Petrochemical and Refinery – Gate valves are used with crude oil and hot hydrocarbons; globe valves are used to throttle distillation columns.

- Water and Wastewater treatment– Lift check valve- this type of valve avoids back-pressure pumps; Gate valve- this has great volumes of treated water.

- Power Generation – Shut-off in steam and condensate lines is by means of gate valves; condensate re-entry into boilers by lift check valves.

- Food and Beverage Globe valves regulate the flow of syrup; control check valves prevent contamination of bottling line.

- Pharmaceutical – Cleanable, gate type valves maintain sterility; globe types provide better, accurate mixing.

Why Choose XSIS Valves?

As one of the top valve manufacturers and exporters in Ahmadabad, we combine innovation, quality, and precision to deliver valves that perform consistently across industries.

Our Competitive Advantages:

Proven Expertise: 17+ years of trusted valve manufacturing experience.

Global Reach: Recognized valve exporter in Ahmadabad with clients across multiple countries.

Uncompromised Quality: Adherence to ISO 9001:2015 and international standards.

Durability & Reliability: Valves designed for long-lasting operation in harsh environments.

Customization: Tailor-made valve solutions for diverse industrial needs.

Sustainability Focus: Environmentally responsible manufacturing processes.

Xsis Valves

Our Recent Blogs

Reliable Forged Steel Valve Supplier in Ahmedabad

Served By

We provide a comprehensive selection of valves tailored for various industries in Ahmadabad, including Plumbing, HVAC, Fire-Fighting, Power, Oil & Gas, Steel & Mining, Boilers, Pharmaceuticals, Chemicals & Fertilizers, LNG, Cryogenics, and Marine applications. Our in-house design facility utilizes advanced computer modeling software to engineer specialized valves for critical applications.

Oil & Gas

LNG & Cryogenic

Marine & Water

Chemicals & Fertilizer

Steel & Mining

Power

Advantages Of Forged Steel Gate Valve

- Forging metal is melted and shaped with bands in the middle of the metal which creates valves that can withstand more pressure and temperature thus improving service life and minimizing replacement.

- Tight uniform seats minimize leakage and the process integrity remains high which is important when small leaks result in downtime or even hazards.

- The reduced number of wear parts and a strong construction results in reduced number of repairs and reduced cost of operations.

- Valves are available in numerous dimensions, pressure rating, types (swing or diaphragm or ball-actuated). They are specifically designed and made to fit pipeline dimensions and process requirements.

- The forging process eliminates internal defects like porosity, shrinkage, and gas pockets common in castings. This results in a much denser, non-porous structure with excellent grain flow, leading to higher overall strength and fatigue resistance under thermal cycling and shock.

- These valves offer better resistance to localized corrosion and erosion compared to cast valves. They also ensure strict material quality control and meeting industry-standard specifications.

Key Factors to Consider When Choosing Forged Steel Gate Valve

- Evaluate Pressure and Temperature. Selecting the pressure class and temperature rating (as high as 300 degrees F) of the valve to match your pipeline is one of the most important key factors, as it assures the quality performance and risk of damage is reduced.

- Material Compatibility– Confirm forged steel quality (e.g. 316L stainless, alloy 80) is not prone to corrosion in case the fluid has acids or chlorides. So one should consider its construction material before choosing for their preferred system.

- Actuation Preference– The simplicity and lower cost are associated with manual valves. Automated systems are provided with remote control and more prompt response by electric or pneumatic actuators.

- Records and Certifications- Check that the valve is of ANSI or ISO standard, that the manufacturer provides maintenance manuals and warranty information because taking account of such features may avoid risk of damage in future.

Maintenance Guide for Forged Steel Gate, Globe & Lift Check Valves

- Regular inspection like checking seats, wear or corrosion trim and stems quarterly to detect any issues on time.

- Lubrication of Moving Parts- Keeping detailed eye on the moving parts like Coat stems and gear mechanisms with approved lubricants at least every six months to ensure friction is minimized and mechanism does not become stuck.

- Seal Replacement- Replacement of O-rings, gaskets or diaphragms; it should be replaced every year or when wear appears very visible and which should be shut off closely.

- Electrically agitated or pneumatically agitated actuated valves have calibrated twice per year to ensure accurate operation and prevent component stress.

- Perform a system pressure test and a leak isolation test annually or after any major repair. This confirms the integrity of the seals and the main body, ensuring the valve holds the required pressure without external or internal leakage (seat leakage).

- Maintain a detailed log of all maintenance activities, including inspection dates, parts replaced (with serial/lot numbers), calibration results, and observations. This is crucial for predictive maintenance planning and warranty compliance..